Tutti i prodotti

-

Battipalo idraulico

-

escavatore montato battipalo

-

Martello elettrico vibratore

-

Piledriver laterale della presa

-

Quattro piloti eccentrici

-

Guida di 360 gradi

-

Mini Excavator Pile Driver

-

Attrezzatura concreta di azionamento di mucchio

-

Pile driver lungo boom

-

Asta meccanica

-

Parti del piledriver

-

Perforatrice del foro

-

Taglierina idraulica della barriera

-

Trencher idraulico

-

Conduttore di pile fotovoltaiche

-

Palancola che guida macchina

-

Martello idraulico

-

Interruttore idraulico del mucchio

HDY22 Martello idraulico a colpo di pila

Contattimi gratis campioni e buoni.

Whatsapp:0086 18588475571

Chatta: 0086 18588475571

Skype: sales10@aixton.com

Se avete di preoccupazione, forniamo la guida in linea di 24 ore.

xDettagli

| Evidenziare | martello idraulico a colpo,Martello battipalo HDY22,martello idraulico con garanzia |

||

|---|---|---|---|

Descrizione di prodotto

Caratteristiche:

Il martello idraulico della serie HDY, compatibile con le centrali elettriche delle serie E e D, è l'ultima attrezzatura di costruzione di fondazioni ecocompatibile e risparmiatrice di energia sviluppata dalla nostra azienda.Adotta molteplici tecnologie di controllo idraulico ed elettrico avanzate, con caratteristiche quali basso rumore, assenza di inquinamento, elevata efficienza e risparmio energetico, sicurezza e affidabilità e facile utilizzo.Adatti per la costruzione di pilastri prefabbricati e pilastri di tubi in acciaio con diverse condizioni e requisiti geologici, la centrale elettrica D550 può anche essere abbinata a martelli a vibrazione per la costruzione, il che la rende un'ideale nuova generazione di macchine per impianti.

Il sistema idraulico ha un'elevata efficienza, con una corrente di lavoro nominale di circa 200 ~ 250A e può essere dotato di cavi di alluminio quadrati da 120 ~ 150.

Il cavo ha una piccola area di sezione trasversale ed è leggero, riducendo notevolmente l'intensità del lavoro dei lavoratori; il martello idraulico HDY25 è dotato di motore diesel Dongfeng Cummins QSZ13-C550,due pompe a piombo Rexroth A11VLO260 e una pompa a doppia lama Parker T67DB collegate in serie per formare un set di pompe, fornendo potenza di spinta per la costruzione;

Adottando la pompa e la valvola di olio principale Rexroth di primo livello di marca internazionale, con buona stabilità, alta affidabilità e elevata efficienza e risparmio energetico;

Adottando il filtro di ritorno dell'olio Hedeke di prima classe, con elevata portata, elevata precisione di filtrazione e bassa resistenza al ritorno dell'olio, può

Adottando il filtro di ritorno dell'olio Hedeke di prima classe, con elevata portata, elevata precisione di filtrazione e bassa resistenza al ritorno dell'olio, può

migliorare efficacemente la pulizia dell'olio del sistema, ridurre il tasso di guasti delle apparecchiature e prolungare la durata di servizio delle apparecchiature;

Il cilindro idraulico del conduttore di pile adotta sigilli internazionali di prima classe della marca Trelleborg, che hanno un basso tasso di guasti, un'elevata efficienza e una lunga durata di vita;

Adottando un raffreddatore ad alta potenza, abbinato a un regolatore di temperatura per controllare con precisione la temperatura dell'olio,risolve completamente il problema dell'alta temperatura dell'olio nella guida idraulica dei pali, migliora notevolmente l'efficienza di spinta dei pali e prolunga efficacemente la durata di servizio delle guarnizioni e dell'olio idraulico;

La centrale elettrica adotta un serbatoio di carburante di alto livello e una progettazione di ventilazione forzata interna per migliorare l'aspirazione della pompa dell'olio, il motore della pompa dell'olio, l'armadio elettrico o la dissipazione del calore del motore.

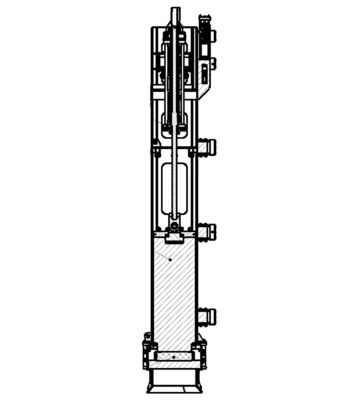

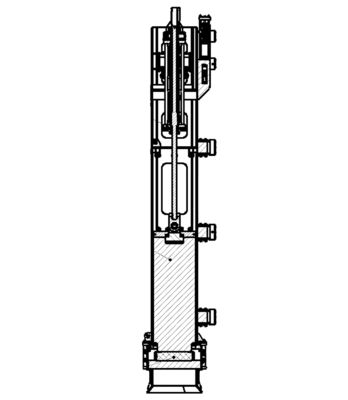

Struttura e aspetto:

Il martello idraulico della serie HDY è composto da parti meccaniche, sistema idraulico e sistema elettrico.che esegue lavori esterni sul martelloIl sistema idraulico è la fonte di alimentazione del martello idraulico, mentre il sistema elettrico è l'input di energia e il centro di controllo del sistema idraulico.

La parte meccanica è costituita dall'assemblaggio del nucleo del martello, dall'assemblaggio del corpo del martello, dall'assemblaggio della bombola dell'olio, dal tappo superiore del tappo, dal tappo inferiore del tappo, dalla pastiglia del martello, dall'anello tampone del tappo del tappo, dal carrello di atterraggio, ecc.Il carrello di atterraggio è utilizzato per l'ascesa e la discesa di martelli idrauliciIl corpo del martello è il corpo di supporto dell'intera parte meccanica, utilizzato per sostenere il cilindro di olio e il nucleo del martello; il tappo superiore della pila è fissato nella parte inferiore del corpo del martello,e il tappo del palo inferiore è manica all'interno del tappo del palo superiore per sostenere il palo del tubo e trasmettere la forza di impattoIl pad del martello e l'anello tampone del tappo del tubo sono montati sul tappo inferiore del tubo per ottenere il trasferimento di energia tra il nucleo del martello e il tappo del tubo; The oil cylinder assembly of the hydraulic hammer achieves the lifting of the oil cylinder piston and the acceleration of gravity through the opening and closing of the plug-in valve installed on the valve block of the oil cylinderL'apertura e la chiusura della valvola del tappo sono controllate dalla valvola solenoide e dalla valvola di sequenza installate sul blocco della valvola della bombola.

Il sistema idraulico è costituito principalmente da una centrale elettrica, tubi di olio, bombole di olio, ecc.

Il sistema elettrico è costituito principalmente da quattro parti: controller, scatola di controllo elettronica, sensori e motore.

Parametro del prodotto:

| Modello | Unità | HDY5 | HDY8 | HDY10 | HDY12 | HDY14 | HDY16 | HDY18 | HDY20 | HDY22 | HDY25 |

| Energia di strilia massima | KN.m | 60 | 120 | 150 | 180 | 210 | 240 | 270 | 300 | 330 | 375 |

| Corso massimo del nucleo del martello |

mm | 1200 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Frequenza di scatto bpm | bpm | Da 30 a 80 | Da 30 a 80 | Da 30 a 80 | Da 30 a 80 | Da 30 a 80 | Da 30 a 80 | Da 30 a 80 | Da 20 a 70 | Da 20 a 70 | Da 20 a 70 |

| Peso del corpo in movimento | kg | 5000 | 8000 | 10000 | 12000 | 14000 | 16000 | 18000 | 20000 | 22000 | 25000 |

| Altezza totale A | mm | 5930 | 6230 | 6750 | 7270 | 7670 | 7670 | 8020 | 7920 | 8220 | 8620 |

| Altezza totale B | mm | 6960 | 7260 | 7760 | 8430 | 8830 | 8830 | 9180 | 9080 | 9380 | 9780 |

| Larghezza anteriore e posteriore C | mm | 1400 | 1520 | 1520 | 1460 | 1460 | 1490 | 1490 | 1720 | 1720 | 1720 |

| Larghezza destra e sinistra D | mm | 1140 | 1260 | 1260 | 1260 | 1260 | 1260 | 1260 | 1500 | 1500 | 1500 |

| Peso del martello idraulico | kg | 9450 | 12650 | 15200 | 20200 | 22600 | 24650 | 27100 | 32350 | 34680 | 38000 |

| Peso del carrello di atterraggio | kg | 200 | 200 | 500 | 500 | 650 | 650 | 650 | 870 | 870 | 870 |